open 10 am - 7 pm

laboratory is closed

Diamond Cutting Stages

Before sparkling in jewelry, a diamond goes a long way to turning into a diamond. Diamond cutting technology has existed for several hundred years and still remains virtually unchanged. Processing of diamond crystals consists of several successive stages: pre-production viewing, marking, sawing, grinding, cutting, polishing and washing. Let's consider each stage in more detail.

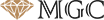

At the first stage of the pre-production review, in essence, planning is done on what will be done with the diamond and what the result will be. They predict the size of the future diamond, its approximate characteristics, the number of diamonds from one crystal, and tense and severely defective diamonds are screened out.

At the next stage of marking, lines are applied to the diamond along which it will be cut.

Diamond sawing, the third stage of processing, allows you to get two or more blanks for future diamonds. This process is quite laborious and requires accuracy, since the quality of the "semi-finished products" of future diamonds depends on this. For cutting diamond crystals, a circular saw with diamond spraying is used.

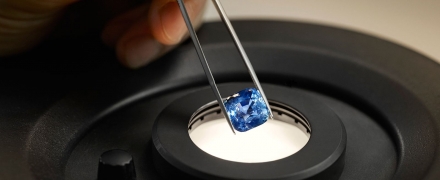

The next stage is considered the most responsible - peeling. The coefficient of use of rough diamonds depends on the quality of work at this stage. The process of grinding or turning consists in making the shape of the future diamond on a special grinding and grinding machine.

After grinding, the diamond preform is cut, that is, the faces are applied to its surface in a certain sequence and in accordance with the parameters of a particular type of cut. Cutting is carried out manually using a diamond disk and pastes of different hardness.

Further manipulations taking place with the already "almost brilliant" are polishing it. It consists in improving the surface quality of the faces deposited on the crystal. Discs are also used for this purpose, but already using polishing pastes.

And the last stage is flushing. It is designed to remove dirt and oil from the surface of a diamond that have fallen on it during production. The diamonds are washed in several stages using various liquids, including sulfuric acid, alcohol and distilled water.

В геммологической практике бывают весьма увлекательные случаи с диагностикой ювелирных вставок

Но помимо редкости цвета и высокой стоимости таких камней, многие розовые камни выделяются одной замечательной особенностью – они проявляют плеохроизм, то есть в зависимости от положения осмотра камня он может иметь дополнительные оттенки – оранжевый или пурпурный.

Currently, gemstones are produced by two fundamentally different technological methods - the High Pressure - High Temperature method (“HPHT”, High-pressure & High-temperature) and the Chemical Vapor Deposition (“CVD”, Chemical vapor deposition) method. The "HPHT" method is the most tested classical synthesis method, which can be used both carbon deposition on diamond from flux melts and catalytic reactions. In "CVD" synthesis, diamond growth occurs on a seed during carbon deposition mainly from a gaseous medium at relatively low temperatures and pressures.

Jewelry and precious stones are just such a category of goods, when buying which you need to pay attention to many criteria.

Sogdianite is a rather rare mineral and more often it can be found as a collection material (moreover, in systematic collections), and it is extremely rare in jewelry.